Creating and managing a brand of ready-to-wear clothing

Limitless manages and coordinates ready-to-wear clothing projects. We have selected the best partners in the textile sector in Mauritius. From the creation of the folder to production, each step is carefully managed and controlled. We also provide advice to the customers.

Communication

Good communication is key for the success of any project. We make it a point to listen to our customers and fully understand their needs and requirements. We can be reached on SMS, email or telephone.

Technical Drawings

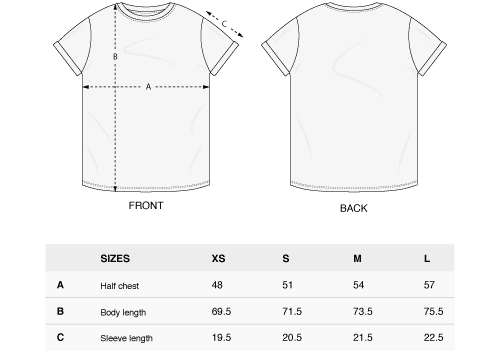

After receiving the technical drawings of each model of clothing, we study them carefully. If the client does not have a specific model we design one on site in Mauritius with his collaboration by email or telephone. The patterns are usually sent to him by email and he discusses any changes to be made with us.

Folder

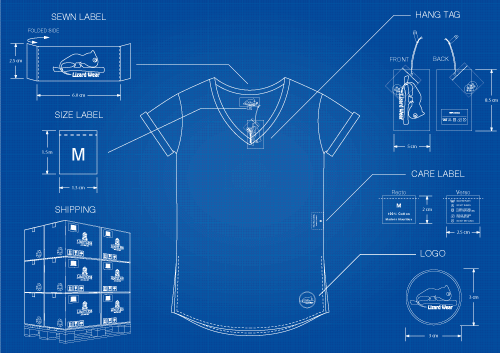

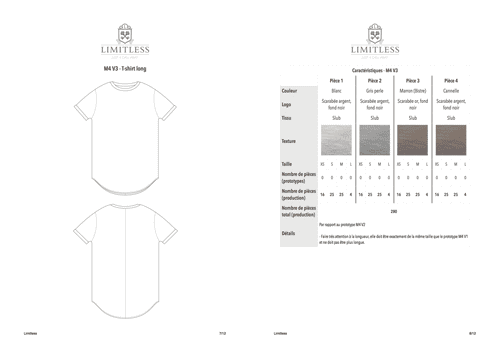

We create a complete file which includes all the necessary information for the smooth running of the project, such as technical drawings, models, fabrics to use, colours, the number of pieces for each size, handling of technical details, etc.

Samples

Some clients send us samples of items of clothing they have already had made by post. These can serve as a model for production or changes can be made to the design, which can be used as the prototypes.

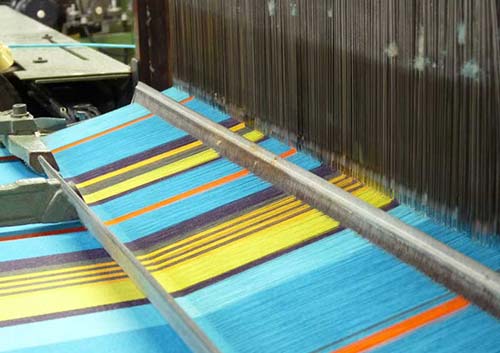

Fabric

The search for and selection of the fabric is done according to customer requirements (composition, weaving, colours, etc.). Samples are sent to the customer and he decides. We partner with specialized factories that offer the possibility of entirely creating a fabric with the desired characteristics.

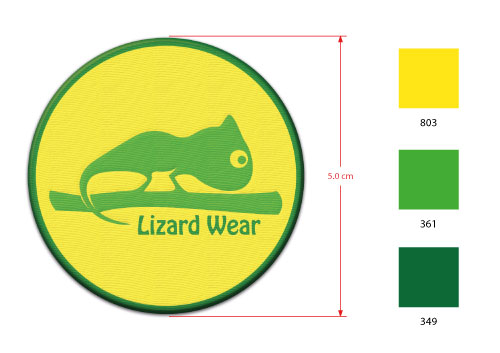

Patches and embroidery

Options such as patches or embroidery are made on site in Mauritius. Our partners can produce customised patches and embroidery according to customer requirements. Simply provide the logo file, the dimensions of the shield, the colour reference (Pantone, hex code, RGB code, CMYK code, HSB code, etc.) and the type of desired embroidery. Samples are made and sent to the customer. If he is completely satisfied, production is launched, and if not, we make the necessary changes to badges samples and they are again sent to the client for approval. If the logo is to be changed or even entirely created, our graphic designers will take care.

Fabric Labels

The fabric labels located at the back of the clothes are made with the greatest care, according to the specifications, by the best and specialised factories that we have selected.

Cardboard labels "Hang Tag"

With hang tag, the visual aspect of the brand is enhanced. These can differ in form, thickness, colour, texture and can include strings or pins for example. It is also convenient to attach accessories such as buttons to them.

Prototypes

Once all the details have been finalised, prototypes are made in fabrics and colours chosen and fitted possible embroidery or patches made.

Production

After all the details have been settled and confirmed by the customer, production is launched.

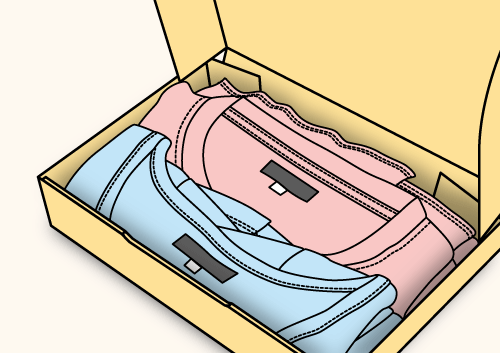

Dispatching of the production

Depending on the weight and volume of production, we obtain quotations from several companies dealing with cargo and the client makes his choice.

Project

Whether you have a large or even a small project, do not hesitate to contact us in order to discuss. We handle all sizes of projects. It is also possible to use Limitless only at one step, such as creating badges for example. For each step, before starting production, one or more samples are made and sent to know more about the product.

The advantages of entrusting your project to Limitless are many. A quality folder with pleasant and explicit illustrations is created. The cost of production in Mauritius is very competitive and of quality compared to other countries.